Recyclability Certification of PE/PA

Testing Scheme at cyclos HTP

Polyethylen/polyamide (PE/PA) film waste streams are already recycled since many years on larger scale. On the one side current waste sorting centers do not separate PE/PA from the PE waste streams and PE/PA is already nowadays recycled in the PE films waste stream, on the other side it is common practice for barrier film producers to recycle their multilayer film waste streams internally and feed it back under PE condition to yield film products with virgin quality.

Practical proof is hence given, but to obtain official and consumer acceptance, certification is needed to prove PE/PA recyclability independently.

On request of BASF, PE/PA compatibility testing with PE flexibles recycling was started by the independent institute cyclos-HTP GmbH in 2021 and finalized in 2023, with positive conclusion also on high barrier and laminated PE/PA structures.

According to the CHI-C8-PEF-1/4.1 protocol to test “Basic Recycling Application Compatibility for PE-based Flex. Packaging” the effect of polyamide in PE film recyclate on injection molding as well as blow film applications is evaluated.

The test matrix included:

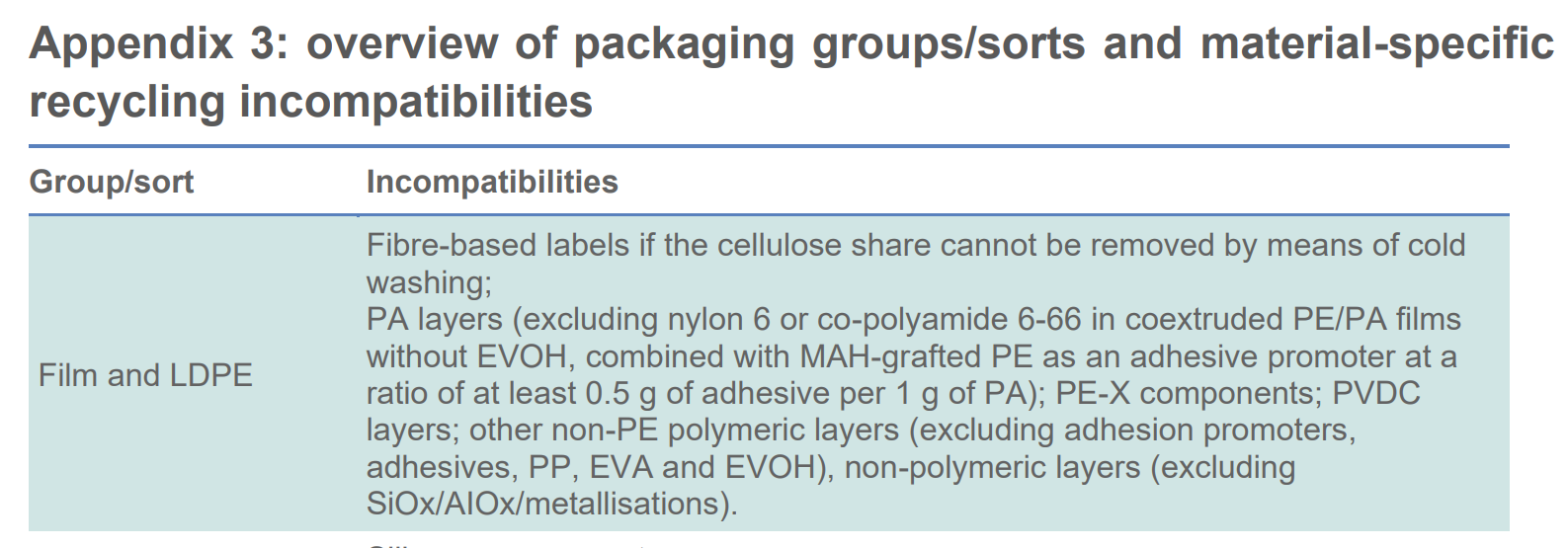

- Coextruded PE/PA films with up to 30% polyamides (optionally with up to 5 % EVOH) and 0,5 g tie layer/ g PA

- Coextruded PE/PA films with up to 30% polyamides (optionally with up to 5 % EVOH) and 0,5 g tie layer/ g PA + 0,15 g compatibilizer / g PA

- Laminated PE/PA film with 3,5 % compatibilizer in the PE matrix

As tie layer as well as compatibilizer, polyethylene with varying grafting densities of maleic acid anhydride is used (PE-g-MAH).

Test results proving recycling compatibility

The cyclos-HTP test protocol distinguishes between two levels of recyclability. In the test protocol, successful processing and application testing of a recyclate blend with 5% of the test material leads to a certification as recycling compatible (CHI5). If the tested material (here PE/PA regranulate) shows even no negative impact at 30% in the recyclate blend, the test component is regarded as valuable material in the tested recycling stream (CHI30). To pass the protocol, no tested item on processability, optical as well as mechanical properties of the recyclate must be below the results of a recyclable benchmark.

The results show that for coextruded structures the tie layer is sufficient to compatibilize the polyamide in the PE recycling stream. In laminated structures a compatibilizer must be added into the PE part of the film structure. As all structures passed the requirements at market common levels in the waste stream (CHI5), the following independent certification was granted by Institute cyclos-HTP:

In 2022, the studies on coextruded PE/PA were already acknowledged by Zentrale Stelle Verpackungsregister in Germany: the minimum standard for determining the recyclability of packaging subject to system participation pursuant to Section 21 (3) VerpackG was updated to not regard coextruded PE/PA films with the required level of PE-g-MAH as impediment on recyclability of PE film waste streams anymore.

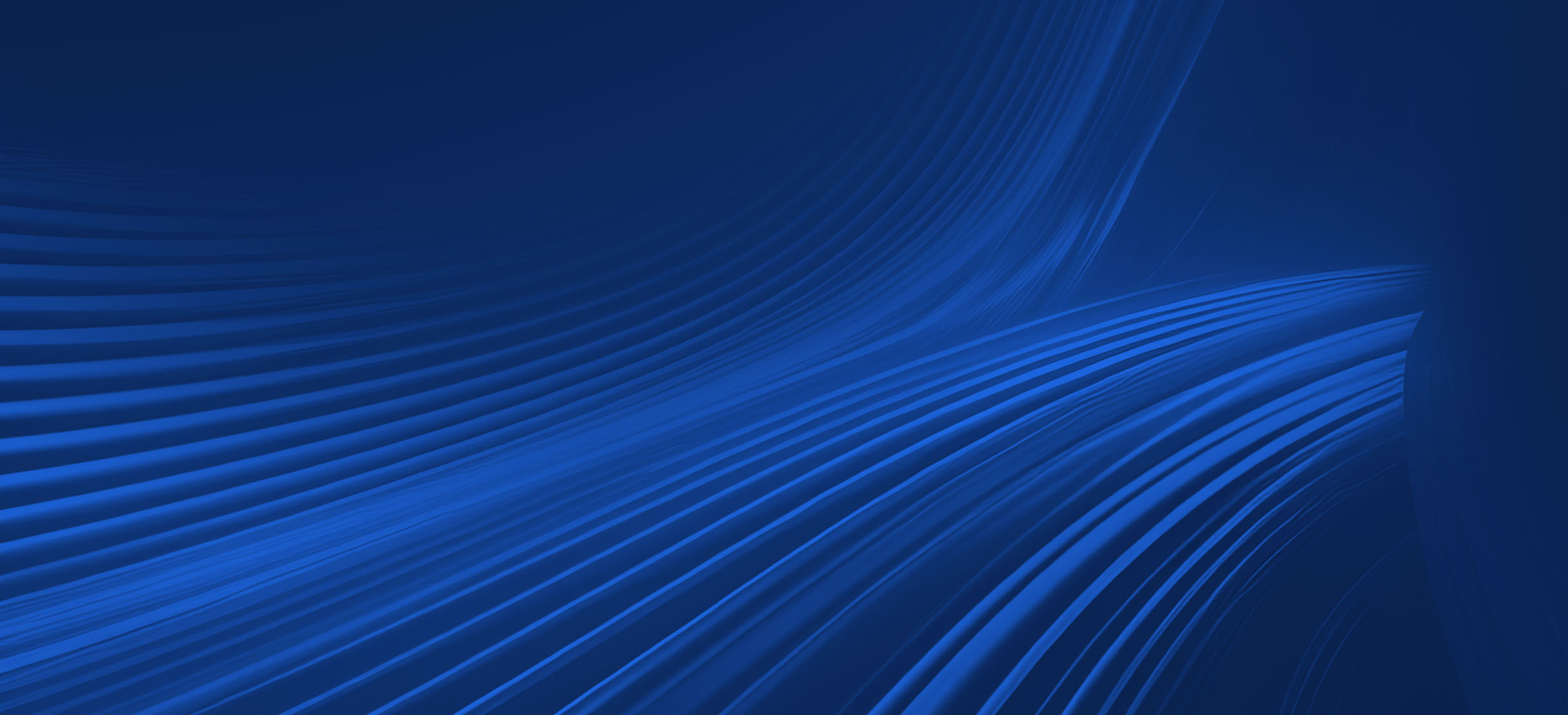

Figure: Excerpt of Appendix 3: minimum standard for determining the recyclability of packaging subject to system participation pursuant to Section 21 (3) VerpackG ( Minimum_standard_Packaging-Act_2022.pdf (verpackungsregister.org) )

How to obtain full recyclability for PA containing multilayer structures?

While all coextruded films with >/= 0,5 g tie layer per g polyamide can be certified compatible with PE film recycling, PA will even be counted as a valuable material in the PE waste stream if additional compatibilizer is added to the primary film structure. This compatibilizer (PE-g-MAH with high grafting densities, e.g., Fusabond® E 226 or equivalent PE-g-MAH structures) has to be added in a PE layer that is not directly in contact with PA, to preserve it as a reactive species active during the regranulation process. If the compatibilizer is added with >/= 0,15 g per g polyamide, the polyamide is regarded as a valuable component in the PE waste stream, as stated in the following certificates:

Summary:

The tested PE/PA structures are compatible with the PE recyling stream with neutral (or even beneficial) effect on the final recyclate product quality.

- All coextruded films (PE/PA as well as PE/PA/EVOH), with a tie layer ratio of > 0,5 gr tie laye/gr PA are recycling compatible in the PE film waste stream.

- For coextruded films, the recyclate properties at higher PA concentration in the recyclate can be further improved if a compatibilizer is added, offering up to 100% recyclability certificates. EVOH will be deducted from the valuable material content.

- Also laminated films with PA and a PE-g-MAH compatibilizer can be regarded as recycling compatible – recyclability: 100%- % PA content- % adhesive

For detailed information please check: Mechanical Recycling (basf.com) or contact info@advanced-packaging-association.org